Each of the 550 models were hand built, and for the team of Wendler coach makers to maintain a consistent shape in the production of the new Porsche race car, they first created wooden bucks to ensure each aluminium panel they hand crafted, fitted exactly onto the buck and in turn onto the tubular steel chassis it was destined for. They would skilfully work the aluminium and fit it to the buck until the perfect curves synonymous to the spyder were achieved. From historical documents and evidence of hammer marks during restorations, it is believed that Wendler did not use english wheels or power hammers when shaping the bodies for the 550s. All panels were shaped using hand hammers, shot bags and dollies, with panels gas welded together to create a strong join seam. Rivets were also used extensively throughout the interior panels, but not as uniform as you would expect in the finish.

It is estimated that there were two bucks used in the Wendler factory for the customer production run. Slight variations to the rear licence plate section indicate a different buck used on some of the builds. There is a buck located at the Gmünd Porsche Automuseum in Austria, but due to the excellent condition of it, it could be a reproduction based on an original.

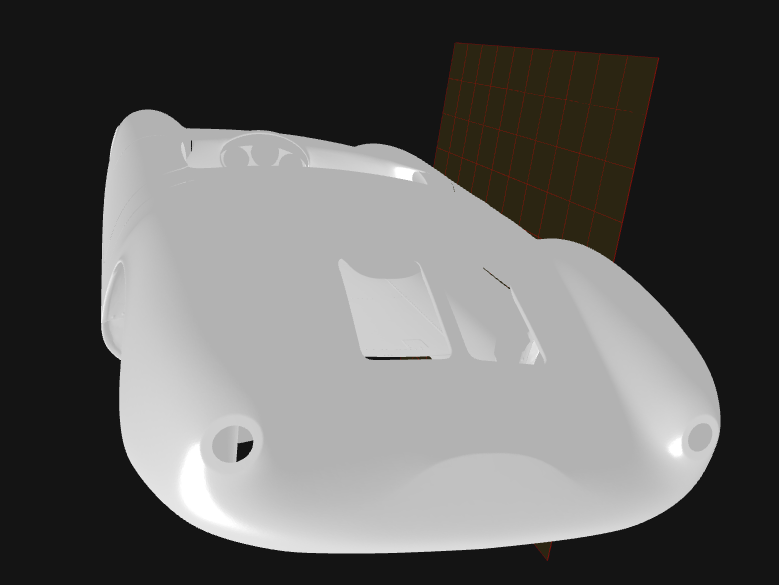

With technology developments in 3D scanning, accurate bucks within 1/10mm are being created based on original 550s being scanned for restorers and replica builders. With the use of a CNC cutter, whole body sections can be carved away from solid timber blocks and assembled together. Others use a skeleton process of body sections meticulously shaped and assembled together to create the whole body as a buck.